RECO Hydro-Pneumatic Tanks

RECO Hydro-Pneumatic Tanks

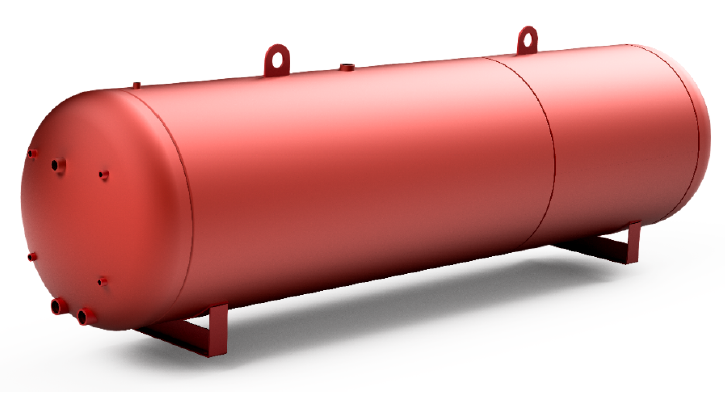

RECO hydro-pneumatic tanks are designed to store both water and compressed air. Without an internal bladder to separate the two, the compressed air is in direct contact with the stored water and acts to either absorb or exert pressure on the water.

RECO hydro-pneumatic tanks are designed to store both water and compressed air. Without an internal bladder to separate the two, the compressed air is in direct contact with the stored water and acts to either absorb or exert pressure on the water.

STOCK HYDRO-PNEUMATIC TANKS SIZES 1,000 – 5,000 GALLON.

READY TO SHIP AT TIME OF ORDER.*

Custom pressure ratings and tanks available up to 35,000 gallons

Key Features and Benefits

RECO hydro-pneumatic tanks are used in well water systems, fire protection systems, or as buffer tanks in large pumping systems to improve system performance in several ways. For pressurization the RECO hydro-pneumatic tanks maintains a minimum positive pressure throughout the system. This enables a rapid response to demands for water without having to continuously run the system pumps. The RECO hydro-pneumatic tanks also dampens pressure fluctuations and any hydraulic shock (water hammer) caused by pump cycling or rapid valve closures. This helps extend the life of those components.

The RECO hydro-pneumatic tank can also serve as a back-up safety device, supplying water for critical needs during unplanned power outages. All tanks include (2) connections for a sight glass and separate relief valve, air, inlet, vent, and drain connections at no additional charge. A 12” x 16” manway is also included as standard.

RECO hydro-pneumatic tanks are designed for horizontal use, above or below grade, with storage capacities from 1,000 to 35,000 gallons. Their interiors are epoxy lined as standard to prevent corrosion, and they work best with an air cushion of about ¼ of the tank volume.

*Applies only if selected size is in stock at time of order. Inquire at sales@reco-cs.com for current sizes in stock.

Specifications and Ratings

- MaterialsASTM SA-516-70 carbon steel tanks as standard

- SpecificationsDesigned to ASME B & PV Code, Section VIII, Division I

- Ratings150 PSIG max design pressure, 250 °F max design temperature

- ConnectionsAll connections over 2½” are ANSI 150 lb. RFSO flanges

- InteriorsSandblasted per SSPC-SP 10 with an NSF 61 compliant epoxy lining

- ExteriorsSandblasted per SSPC-SP 6 and coated with a red oxide primer

- OrientationHorizontally mounted with (2) support saddles (loose or attached)