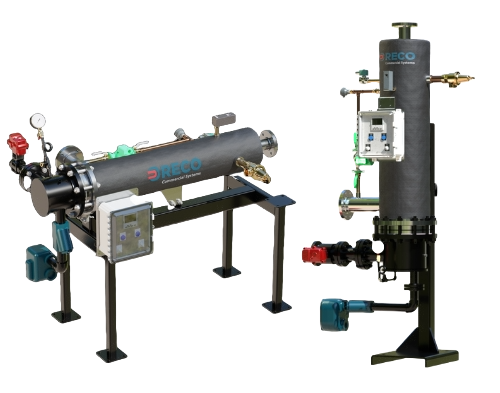

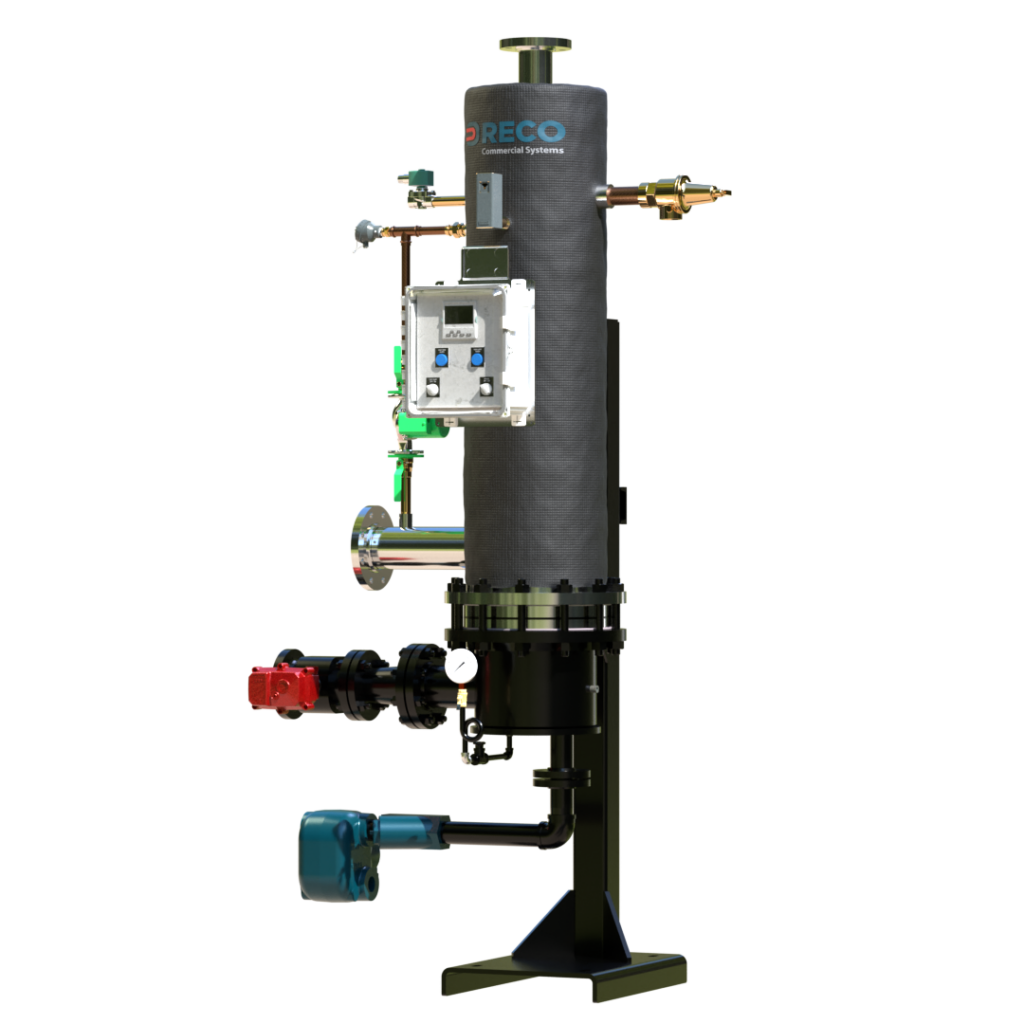

HX2 Series Domestic Water Heaters

The HX2 Series is RECO’s next generation of in-line heaters. Lighter, smaller, and more thermally efficient than ever before, the HX2 delivers up to 6.0 million BTU/HR of heating as standard, with higher capacities possible.

The HX2 is a semi-instantaneous water heater using available steam or boiler water as the heating medium. Designed to the guidelines of TEMA, BOCA and IAPMO, these heaters can heat up to 150 GPM from 40 °F to 140 °F as standard, with higher capacities possible.

At the heart of the control system is the Control Master II® panel with a digital PAC controller. The Control Master II has an easy-to-navigate LCD panel for local monitoring and set point adjustment. It accepts remote set point changes and can re-transmit water temperature by analog signals or digital signals via standard Modbus® or BACnet® network communications protocols.

An electrically operated, fast-acting V-ball control valve is used to modulate the flow of the heating fluid. It has a 100:1 rangeability which gives excellent control at all flow rate and will fail closed in the event of loss of main power. Soft valve seats provide tight valve shut-off and prevent temperature rises at low load due to valve seat leakage.

Key Features and Benefits

- Safety features include a pressure/temperature (P/T) relief valve, solenoid-operated dump valve, high and low control panel alarm settings, and an automatic fail-closed steam inlet control valve.

- Lightweight, compact design easily fits through standard freight elevators.

- High accuracy temperature control of ±4 °F achieved.

- Continuous forced re-circulation ensures a uniform temperature distribution across all temperature sensors while also reducing scaling and sediment build-up on the tube bundles in the process.

- ASME constructed and stamped tank assures safe operation to 150 PSIG.

- All wetted parts on the heated side are lead-free and comply with NSF Standard 61 and the requirements of the U.S. Safe Drinking Water Act.

Materials of Construction

The standard HX2 tank and couplings are 316L stainless steel passivated to ASTM A380 and A967. Piping is carbon steel, welded or threaded as appropriate. All units come with a flexible insulation jacket conforming to ASHRAE Std. 90.1, and the support stand and heating bundle head are powder coated for added durability.

HX2 Performance Ratings

- Recovery rates5 to 150 GPM

- Steam supply pressureUp to 100 PSIG

- Cold water inlet pressureUp to 150 PSIG

- Heated water outlet temperatureUp to 210°F

- Design ratingASME Boiler & PV Code “U” stamped